Add to Cart

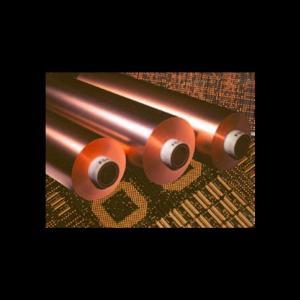

Ed Copper Foil Shielding 0.1 Mm Copper Sheet RF Cage 1320mm Width

Copper Foil Types

1. According To The Thickness.

Thick copper foil (>70μm),

Conventional thickness copper foil (18μm — 70μm).

Thin copper foil (12μm –18μm).

Ultra-thin copper foil (<12μm).

2. According To The Surface Condition

Single-sided treated copper foil (single-sided wool),

Double-sided treated copper foil (double-sided thick),

Smooth-treated copper foil (double-sided wool),

Double-sided smooth copper foil (double-gloss)

Very low-profile copper foil Foil (VLP copper foil)

3. According To The Production Method

Electrolytic copper foil (ED Foil)

Rolled copper foil.

4. According To The Application Scope

Copper clad laminates (CCL) and copper foils for printed circuit boards (PCB):

CCL and PCB are the most widely used fields of copper foil.

PCB has now become an indispensable main component for most electronic products to achieve circuit interconnection.

The copper foil has now become the key material of PCB. It supports and interconnects components in electronic complete products.

At present, most of the applications in the CCL and PCB industries are electrolytic copper foils.

Copper foil for the lithium-ion secondary battery:

According to the working principle and structural design of lithium-ion batteries, anode materials.

Such as graphite and petroleum coke need to be coated on the conductive current collector.

Because of its good conductivity, soft texture, mature manufacturing technology, and relatively low price,

the copper foil has become the first choice for negative electrode current collectors of lithium-ion batteries.

Copper foil for electromagnetic shielding.

Mainly used in hospitals, communications, military and other fields that require electromagnetic shielding.

Because the rolled copper foil is limited by the width, the electromagnetic shielding copper foil is mostly electrolytic copper foil.

| Item | Unit | Condition | Specification value | Inspection frequencies | Test method | |||

| 8 um | 10 um | 12 um | 18 um | |||||

| Purity | % | A | ≥ 99.9 | C | IPC-TM-650-2.3.15 | |||

| Area weight | g/㎡ | A | 72±4 | 89±5 | 107±5 | 155±8 | А | IPC-TM-650-2.2.12 |

| Drum Side Roughness (Ra) | um | A | ≤ 0.4 | А | IPC-TM-650-2.2.17 | |||

| Electrolyte Side Roughness(Rz) | um | A | ≤ 3.5 | А | IPC-TM-650-2.2.17 | |||

| Tensile strength | kg/mm2 | A | ≥ 35 | А | IPC-TM-650-2.4.18 | |||

| Elongation | % | A | ≥ 3 | ≥ 4 | А | IPC-TM-650-2.4.18 | ||